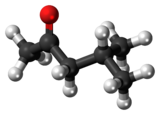

Methyl isobutyl ketone

|

|

|

|

| Names | |

|---|---|

|

Preferred IUPAC name

4-Methylpentan-2-one

|

|

| Other names

4-Methyl-2-pentanone, Isopropylacetone, Hexone, Isobutyl methyl ketone, 2-Methylpropyl methyl ketone, 4-Methyl-2-oxopentane, MIK, Isobutylmethyl ketone, MIBK, Isohexanone

|

|

| Identifiers | |

|

108-10-1 |

|

| 3D model (Jmol) | Interactive image |

| ChemSpider |

7621 |

| ECHA InfoCard | 100.003.228 |

| EC Number | 203-550-1 |

| KEGG |

C19263 |

| PubChem | 7909 |

| RTECS number | SA9275000 |

| UNII |

U5T7B88CNP |

|

|

|

|

| Properties | |

| C6H12O | |

| Molar mass | 100.16 g/mol |

| Appearance | colorless liquid |

| Odor | pleasant |

| Density | 0.802 g/mL, liquid |

| Melting point | −84.7 °C (−120.5 °F; 188.5 K) |

| Boiling point | 117 to 118 °C (243 to 244 °F; 390 to 391 K) |

| 1.91 g/100 mL (20 °C) | |

| Vapor pressure | 16 mmHg (20 °C) |

| -70.05·10−6 cm3/mol | |

|

Refractive index (nD)

|

1.3958 |

| Viscosity | 0.58 cP at 20.0 °C |

| Structure | |

| 2.8 D | |

| Hazards | |

|

EU classification (DSD)

|

Flammable (F) Harmful (Xn) |

| R-phrases | R11, R20, R36/37, R66 |

| S-phrases | (S2), S9, S16, S29 |

| NFPA 704 | |

| Flash point | 14 °C (57 °F; 287 K) |

| 449 °C (840 °F; 722 K) | |

| Explosive limits | 1.2%-8.0% (93 °C) |

| US health exposure limits (NIOSH): | |

|

PEL (Permissible)

|

TWA 100 ppm (410 mg/m3) |

|

REL (Recommended)

|

TWA 50 ppm (205 mg/m3) ST 75 ppm (300 mg/m3) |

|

IDLH (Immediate danger)

|

500 ppm |

| Related compounds | |

|

Related ketones

|

Methyl isopropyl ketone 2-Pentanone Diisobutyl ketone |

|

Related compounds

|

2-Methylpentan-4-ol |

|

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

|

|

|

|

|

| Infobox references | |

Methyl isobutyl ketone (MIBK) is the organic compound with the formula (CH3)2CHCH2C(O)CH3. This colourless liquid, a ketone, is used as a solvent for gums, resins, paints, varnishes, lacquers, and nitrocellulose.

Methyl isobutyl ketone is manufactured from acetone via a three-step process. Firstly acetone undergoes an aldol condensation to give diacetone alcohol, which readily dehydrates to give mesityl oxide. Mesityl oxide can then be hydrogenated to give MIBK:

Industrially, these three steps are combined. Acetone is treated with a strong acidic, palladium-doped cation exchange resin under medium pressure of hydrogen. Several million kilograms are produced annually. In 2003, the industrial production capacity for MIBK in the United States was 88,000 tons.

MIBK is used as a solvent for nitrocellulose, lacquers, and certain polymers and resins.

Another major use is as a precursor to N-(1,3-dimethylbutyl)-N'-phenyl-p-phenylene diamine (6PPD), an antiozonant used in tires. 6PPD is prepared by reductive coupling of MIBK with 4-aminodiphenylamine.

Unlike the other common ketone solvents, acetone and MEK, MIBK has quite low solubility in water, making it useful for liquid-liquid extraction. It has a similar polarity to ethyl acetate, but greater stability towards aqueous acid and base. It can be used to extract gold, silver and other precious metals from cyanide solutions, such as those found at gold mines, to determine the levels of those dissolved metals. Diisobutyl ketone (DIBK), a related lipophilic ketone, is also used for this purpose. Methyl isobutyl ketone is also used as a denaturing agent for denatured alcohol. When mixed with water or isopropyl alcohol MIBK serves as a developer for PMMA electron beam lithography resist. MIBK is used as a solvent for CS in the preparation of the CS spray used currently by British police forces.

...

Wikipedia