Mihama Nuclear Power Plant

| Mihama Nuclear Power Plant | |

|---|---|

Mihama Nuclear Power Plant

|

|

| Country | Japan |

| Location | Mihama, Fukui Prefecture |

| Coordinates | 35°42′12.51″N 135°57′48.88″E / 35.7034750°N 135.9635778°ECoordinates: 35°42′12.51″N 135°57′48.88″E / 35.7034750°N 135.9635778°E |

| Status | Operational |

| Construction began | 1 February 1967 |

| Commission date | 28 November 1970 |

| Operator(s) | The Kansai Electric Power Company, Inc. |

| Nuclear power station | |

| Reactor type | PWR |

| Cooling source | Nyunoura bay, Sea of Japan |

| Cooling towers | no |

| Power generation | |

| Units operational | 1 x 826 MW |

| Units decommissioned | 1 x 340 MW 1 x 500 MW |

| Nameplate capacity | 826 MW |

| Average generation | 5,500 GW·h |

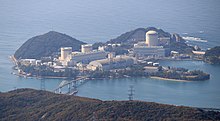

The Mihama Nuclear Power Plant (美浜発電所 Mihama hatsudensho?, Mihama NPP) is operated by The Kansai Electric Power Company, Inc. and is in the town of Mihama, Fukui Prefecture, about 320 km west of Tokyo. It is on a site that is 520,000 m2 of which 60% is green space. Mihama - 1 was the first nuclear reactor to generate electricity commercially in Japan and was commissioned in 1970.

The Mihama NPP has been notable beyond most nuclear plants due to the severity of accidents that have happened there, the 2004 steam explosion in particular.

Unit 2 steam generator had one tube fully break. This triggered a SCRAM with full activation of the Emergency Core Cooling System. Eventually, a small amount of radiation was released to the outside.

Unit 2 steam generators had two holes open simultaneously. There was no radioactive release to the environment.

On 9 August 2004, an accident occurred in a building housing turbines for the Mihama 3 reactor. Hot water and steam leaking from a broken pipe killed five workers and resulted in six others being injured. The accident had been called Japan's worst nuclear power accident before the crisis at Fukushima I Nuclear Power Plant.

The Mihama 3 is an 826 megawatts electric, 3-loop Westinghouse type pressurized water reactor (PWR) which has been in service since 1976. The pipe rupture occurred in a 55.9 centimeter (cm) (22 inch) outside diameter pipe in the ‘A’ loop condensate system between the fourth feedwater heater and the deaerator, downstream of an orifice for measuring single-phase water flow. At the time of the secondary piping rupture, 105 workers were preparing for periodic inspections to commence.

A review of plant parameters did not uncover any precursor indicators before the accident nor were there any special operations that could have caused the pipe rupture. An investigation concluded that water quality had been maintained since the commissioning of the plant, however the failing pipe had been omitted from an initial inspection plan and quality management systems were ineffective.

...

Wikipedia