Maleic anhydride

|

|

|||

|

|||

| Names | |||

|---|---|---|---|

|

Preferred IUPAC name

Furan-2,5-dione

|

|||

| Other names

Maleic anhydride

cis-Butenedioic anhydride 2,5-Furanedione Maleic acid anhydride Toxilic anhydride |

|||

| Identifiers | |||

|

108-31-6 |

|||

| 3D model (Jmol) | Interactive image | ||

| ChEBI |

CHEBI:474859 |

||

| ChEMBL |

ChEMBL374159 |

||

| ChemSpider |

7635 |

||

| ECHA InfoCard | 100.003.247 | ||

| EC Number | 203-571-6 | ||

| PubChem | 7923 | ||

| RTECS number | UE5950000 | ||

| UNII |

V5877ZJZ25 |

||

|

|||

|

|||

| Properties | |||

| C4H2O3 | |||

| Molar mass | 98.06 g·mol−1 | ||

| Appearance | White crystals or needles | ||

| Odor | irritating, choking | ||

| Density | 1.48 g/cm3 | ||

| Melting point | 52.8 °C (127.0 °F; 325.9 K) | ||

| Boiling point | 202 °C (396 °F; 475 K) | ||

| Reacts | |||

| Vapor pressure | 0.2 mmHg (20°C) | ||

| -35.8·10−6 cm3/mol | |||

| Hazards | |||

| Safety data sheet | MSDS at J. T. Baker | ||

|

EU classification (DSD)

|

Corrosive (C) | ||

| R-phrases | R22, R34, R42/43 | ||

| S-phrases |

(S2), S22, S26, S36/37/39, S45 |

||

| NFPA 704 | |||

| Flash point | 102 °C (216 °F; 375 K) | ||

| Explosive limits | 1.4%-7.1% | ||

| Lethal dose or concentration (LD, LC): | |||

|

LD50 (median dose)

|

465 mg/kg (oral, mouse) 850 mg/kg (oral, rat) 875 mg/kg (oral, rabbit) 390 mg/kg (oral, guinea pig) 400 mg/kg (oral, rat) |

||

| US health exposure limits (NIOSH): | |||

|

PEL (Permissible)

|

TWA 1 mg/m3 (0.25 ppm) | ||

|

REL (Recommended)

|

TWA 1 mg/m3 (0.25 ppm) | ||

|

IDLH (Immediate danger)

|

10 mg/m3 | ||

| Related compounds | |||

|

Related acid anhydrides

|

Succinic anhydride | ||

|

Related compounds

|

Maleic acid | ||

|

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

|

|||

|

|

|||

| Infobox references | |||

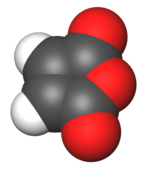

Maleic anhydride is an organic compound with the formula C2H2(CO)2O. It is the acid anhydride of maleic acid. It is a colorless or white solid with an acrid odor. It is produced industrially on a large scale for applications in coatings and polymers.

Maleic anhydride is produced by vapor-phase oxidation of n-butane. The overall process converts the methyl groups to carboxylate and dehydrogenates the backbone. The selectivity of the process reflects the robustness of maleic anhydride, with its conjugated double-bond system. Traditionally maleic anhydride was produced by the oxidation of benzene or other aromatic compounds. As of 2006, only a few smaller plants continue to use benzene.

In both cases, benzene and butane are fed into a stream of hot air, and the mixture is passed through a catalyst bed at high temperature. The ratio of air to hydrocarbon is controlled to prevent the mixture from igniting. Vanadium pentoxide and molybdenum trioxide are the catalysts used for the benzene route, whereas vanadium phosphate is used for the butane route:

The main competing process entails full combustion of the butane, a conversion that is twice as exothermic as the partial oxidation.

The traditional method using benzene became uneconomical due to the high and still rising benzene prices and by complying the regulations of benzene emissions. In addition, in the production of maleic anhydride (4 C-atoms) a third of the original carbon atoms is lost as carbon dioxide when using benzene (6 carbon atoms). The modern catalytic processes start from a 4-carbon molecule and only attaches oxygen and removes water; the 4-C-base body of the molecule remains intact. Overall, the newer method is therefore more material efficient.

...

Wikipedia