Velocity stack

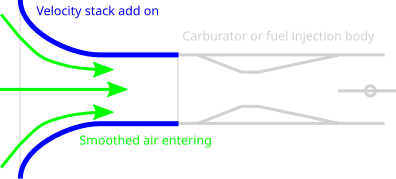

A velocity stack, or air horn, is a trumpet-shaped device of differing lengths which is fitted to the air entry of an engine's intake system, carburetor or fuel injection. It is designed to:

Modern engines universally have tuned intake tract volumes and associated resonance frequencies, designed to provide higher than atmospheric intake air pressure while the intake valves are open - increasing the density of the trapped air in the combustion chamber (higher compression). Modified engines often have the original air box and associated ducting removed and velocity stacks are installed as accessories.

Modern fuel injection systems with a plenum and single air inlet typically incorporate some sort of radiused entrance, designed to improve power, based on air flow increases. Power gains are usually at higher rpm.

In amateur and professional racing, aftermarket velocity stacks are often used, as rules allow, and gains in the order of 2% to 4% can be obtained when inlet radii and stack lengths are optimized for that engine.

OEM automotive manufacturers have many regulations to adhere to. One of these is noise. A properly tuned intake tract produces a rather audible intake noise under high airflow conditions - that is commonly "untuned" to allow the vehicle to pass EPA and DOT noise regulations.

The length of the stack is known to have a direct effect on a particular engine's boosted power range.

Most current aftermarket stacks are designed to be run "in" the airbox and a company that does research well will have some applications that have all the same length and some applications that have differing lengths of stacks on different cylinders.

It is commonly related that "stand off" (air–fuel mix that gets pushed back out of the port, usually at full throttle / low rpm) is somehow captured by installing a longer intake pipe (stack). but, it is actually that the intake valve is closing too late and the combustion chamber is simply overfilling and blowing back out the intake port, before the intake valve closes. A longer inlet pipe will create a later intake pressure wave that will help keep the air in the chamber until the intake valve closes.

...

Wikipedia