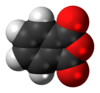

Phthalic anhydride

|

|

|||

|

|||

| Names | |||

|---|---|---|---|

|

Preferred IUPAC name

2-Benzofuran-1,3-dione

|

|||

| Other names

Isobenzofuran-1,3-dione

Phthalic anhydride |

|||

| Identifiers | |||

|

3D model (Jmol)

|

|||

| ChEBI | |||

| ChemSpider | |||

| ECHA InfoCard | 100.001.461 | ||

| RTECS number | TI3150000 | ||

|

|||

|

|||

| Properties | |||

| C8H4O3 | |||

| Molar mass | 148.1 g/mol | ||

| Appearance | white flakes | ||

| Odor | characteristic, acrid | ||

| Density | 1.53 g/cm3, solid; 1.20 g/mL, molten | ||

| Melting point | 131.6 °C (268.9 °F; 404.8 K) | ||

| Boiling point | 295 °C (563 °F; 568 K) sublimates | ||

| 0.62 g/100g (20—25 °C); 19.0 g/100g (100 °C); reacts slowly |

|||

| Vapor pressure | 0.0015 mmHg (20°C) | ||

| -67.31·10−6 cm3/mol | |||

| Hazards | |||

| R-phrases | R22, R37/38, R41, R42/43 | ||

| S-phrases | (S2), S23, S24/25, S26, S37/39, S46 | ||

| NFPA 704 | |||

| Flash point | 152 °C (306 °F; 425 K) | ||

| Explosive limits | 1.7%-10.5% | ||

| Lethal dose or concentration (LD, LC): | |||

|

LD50 (median dose)

|

4020 mg/kg (oral, rat) 1520 mg/kg (oral, mouse) 800 mg/kg (oral, cat) 800-1600 mg/kg (oral, rat) 2210 mg/kg (oral, mouse) |

||

| US health exposure limits (NIOSH): | |||

|

PEL (Permissible)

|

TWA 12 mg/m3 (2 ppm) | ||

|

REL (Recommended)

|

TWA 6 mg/m3 (1 ppm) | ||

|

IDLH (Immediate danger)

|

60 mg/m3 | ||

| Related compounds | |||

|

Related compounds

|

Phthalic acid Phthalimide Phthalide |

||

|

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

|

|||

|

|

|||

| Infobox references | |||

Phthalic anhydride is the organic compound with the formula C6H4(CO)2O. It is the anhydride of phthalic acid. Phthalic anhydride is a principal commercial form of phthalic acid. It was the first anhydride of a dicarboxylic acid to be used commercially. This colourless solid is an important industrial chemical, especially for the large-scale production of plasticizers for plastics. In 2000, the worldwide production volume was estimated to be about 3 million tonnes per year.

Phthalic anhydride was first reported in 1836 by Auguste Laurent. More contemporary routes include catalytic oxidation of ortho-xylene and naphthalene ("Gibbs phthalic anhydride process"), although use of naphthalene has declined. Starting from o-xylene, the oxidation follows the following stoichiometry:

The reaction proceeds with about 70% selectivity. About 10% of maleic anhydride is also produced:

The reaction is catalyzed by a vanadium pentoxide (V2O5) between 320 - 400 °C. The phthalic anhydride is separated from byproducts by a series of "switch condensers". Phthalic anhydride and maleic anhydride are recovered by distillation. Phthalic anhydride can also be prepared from phthalic acid:

The primary use of phthalic anhydride is as a chemical intermediate in the production of plastics from vinyl chloride. Phthalate esters, which function as plasticizers, are derived from Phthalic Anhydride. Phthalate plasticizers are used for the production of flexible PVC products such as cables, pipes and hoses, leather cloth, shoes, film for packaging etc. Phthalic anhydride has another major use in the production of polyester resins and other minor uses in the production of alkyd resins used in paints and lacquers; certain dyes (anthraquinone, phthalein, rhodamine, phthalocyanine, fluorescin, and xanthene dyes); insect repellents; and polyester polyols for polyurethanes. It is also utilized as a rubber scorch inhibitor and retarder.

Phthalic anhydride is a versatile intermediate in organic chemistry, in part because it is bifunctional and cheaply available. Hydrolysis by hot water forms ortho-phthalic acid. Hydrolysis of anhydrides is not typically a reversible process. Phthalic acid is however easily dehydrated to form phthalic anhydride. Above 180 °C, phthalic anhydride re-forms.

...

Wikipedia