Isobutyl alcohol

|

|

|

|

| Names | |

|---|---|

|

IUPAC name

2-methylpropan-1-ol

|

|

| Other names

Isobutyl alcohol, IBA, 2-methyl-1-propanol, 2-methylpropyl alcohol, Isopropylcarbinol

|

|

| Identifiers | |

|

3D model (Jmol)

|

|

| ChEBI | |

| ChemSpider | |

| ECHA InfoCard | 100.001.044 |

| EC Number | 201-148-0 |

| KEGG | |

|

PubChem CID

|

|

| RTECS number | NP9625000 |

| UNII | |

|

|

|

|

| Properties | |

| C4H10O | |

| Molar mass | 74.122 g/mol |

| Appearance | Colorless liquid |

| Odor | sweet, musty |

| Density | 0.802 g/cm3, liquid |

| Melting point | −108 °C (−162 °F; 165 K) |

| Boiling point | 107.89 °C (226.20 °F; 381.04 K) |

| 8.7 mL/100 mL | |

| log P | 0.8 |

| Vapor pressure | 9 mmHg (20°C) |

|

Refractive index (nD)

|

1.3959 |

| Viscosity | 3.95 cP at 20 °C |

| Hazards | |

| Safety data sheet | ICSC 0113 |

|

EU classification (DSD) (outdated)

|

Irritant (Xi) |

| R-phrases (outdated) | R10 R37/38 R41, R67 |

| S-phrases (outdated) | (S2) S7/9 S13 S26 S37/39 S46 |

| NFPA 704 | |

| Flash point | 28 °C (82 °F; 301 K) |

| 415 °C (779 °F; 688 K) | |

| Explosive limits | 1.7–10.9% |

| Lethal dose or concentration (LD, LC): | |

|

LDLo (lowest published)

|

3750 mg/kg (rabbit, oral) 2460 mg/kg (rat, oral) |

| US health exposure limits (NIOSH): | |

|

PEL (Permissible)

|

TWA 100 ppm (300 mg/m3) |

|

REL (Recommended)

|

TWA 50 ppm (150 mg/m3) |

|

IDLH (Immediate danger)

|

1600 ppm |

| Related compounds | |

|

Related butanols

|

n-Butanol sec-Butanol tert-Butanol |

|

Related compounds

|

Isobutyraldehyde Isobutyric acid |

|

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

|

|

|

|

|

| Infobox references | |

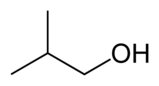

Isobutanol (IUPAC nomenclature: 2-methylpropan-1-ol) is an organic compound with the formula (CH3)2CHCH2OH (sometimes represented as i-BuOH). This colorless, flammable liquid with a characteristic smell is mainly used as a solvent. Its isomers, the other butanols, include n-butanol, 2-butanol, and tert-butanol, all of which are important industrially.

Isobutanol is produced by the carbonylation of propylene. Two methods are practiced industrially, hydroformylation is more common and generates a mixture of isobutyraldehydes, which are hydrogenated to the alcohols and then separated. Reppe carbonylation is also practiced.

Higher-chain alcohols have energy densities close to gasoline, are not as volatile or corrosive as ethanol, and do not readily absorb water. Furthermore, branched-chain alcohols, such as isobutanol, have higher-octane numbers, resulting in less knocking in engines. Although produced naturally during the fermentation of saccharides and may also be a byproduct of the decay process of organic matter, Isobutanol or C5 alcohols have never been produced from a renewable source with yields high enough to make them viable as a gasoline substitute before the 2008 Nature article that produced over 20g/L isobutanol from glucose in E.coli.

To modify an organism to produce these compounds usually results in toxicity in the cell. This difficulty was bypassed by leveraging the native metabolic networks in E. coli but altered its intracellular chemistry using genetic engineering to produce these alcohols. Key pathways in E. coli were modified to produce several higher-chain alcohols from glucose, including isobutanol, 1-butanol, 2-methyl-1-butanol, 3-methyl-1-butanol, and 2-phenylethanol. This strategy exploits the E. coli host's highly active amino acid biosynthetic pathway by shifting part of it to alcohol production. It is proposed that these unusual alcohols can be produced as efficiently as the biosynthesis of ethanol.

...

Wikipedia