Dodecanedioic acid

|

|

| Names | |

|---|---|

|

IUPAC name

Dodecanedioic acid

|

|

| Identifiers | |

|

3D model (JSmol)

|

|

| ChEBI | |

| ChemSpider | |

| ECHA InfoCard | 100.010.680 |

| KEGG | |

|

PubChem CID

|

|

|

|

|

|

| Properties | |

| C12H22O4 | |

| Molar mass | 230.30 g·mol−1 |

| Appearance | White flakes |

| Density | 1.066 g/cm3 |

| Melting point | 127 to 129 °C (261 to 264 °F; 400 to 402 K) |

| Boiling point | 245 °C (473 °F; 518 K) |

| pH dependent | |

| Hazards | |

| Flash point | 220 °C (428 °F; 493 K) |

|

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

|

|

|

|

|

| Infobox references | |

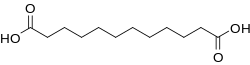

Dodecanedioic acid, informally referred to as DDDA, is a dicarboxylic acid mainly used in antiseptics, top-grade coatings, painting materials, corrosion inhibitors, surfactants, and engineering plastics such as nylon 612.

Experimental work with dodecanedioic acid in type 2 diabetic patients has demonstrated that IV infusion helps to maintain normal blood sugar and energy levels without increasing the blood glucose load in the process.

DDDA is typically produced through two methods. It has traditionally been produced from butadiene using a multi-step chemical process. Butadiene is first converted to cyclododecatriene through a cyclotrimerization process.

Cyclododecatriene (1) is converted to dodecanedioic acid (4) by hydrogenation to cyclododecane (2) followed by air oxidation in the presence of boric acid at elevated temperatures to a mixture of the alcohol (3a) and the ketone (3b). In the final step, this mixture oxidized further by nitric acid.

A biotechnology is used to convert paraffin wax into DDDA with a special strain of Candida tropicalis yeast in a multi-step process. Verdezyne has created a method to use plant-oil sourced feedstocks, which makes it the only producer using renewable feedstocks for DDDA.

...

Wikipedia