David Gestetner

| David Gestetner (eng) Gestetner Dávid (hu) |

|

|---|---|

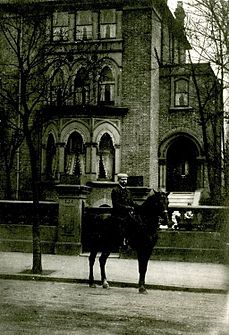

David Gestetner outside his home at 124 Highbury New Park, London, circa 1905

|

|

| Born | 31 March 1854 Csorna, Kingdom of Hungary, Habsburg Empire |

| Died |

8 March 1939 (aged 84) London, United Kingdom |

| Fields | inventor |

| Known for | Gestetner, stencil duplicator, |

| Notable awards | John Scott Medal, Blue Plaque |

| Children | Sigmund Gestetner |

David Gestetner (31 March 1854 in Csorna, Hungary – 8 March 1939 in London) was the inventor of the Gestetner stencil duplicator, the first piece of office equipment that allowed production of numerous copies of documents quickly and inexpensively. He was awarded the John Scott Medal of The Franklin Institute in 1888.

On 12 March 2011 a Blue Plaque was placed on his home at 124 Highbury New Park in north London.

At a young age, Gestetner began work at the in Vienna. One of his tasks was to make copies of the activity at the end of the day by repeatedly handwriting the results. He decided to try to find a better method, and his experiments eventually led him to invent the first method of reproducing documents by use of a stencil. He went on to work in Chicago making kites out of Chinese paper.

Gestetner allegedly perceived the idea of the duplicating method after an ink-spill accident whilst vending kites in Chicago. After a pot of ink spilled over a pile of kites, he found that the same ink pattern remained throughout the pile.

The stencil method used a thin sheet of paper coated with wax (originally kite paper was used), which was written upon with a special stylus that left a broken line through the stencil – breaking the paper and removing the wax covering. Ink was forced through the stencil – originally by an ink roller – and it left its impression on a white sheet of paper below. This was repeated again and again until sufficient copies were produced.

Until this time, any "short copy runs" which were needed for the conduct of a business (e.g., for the production of 10–50 copies of contracts, agreements, or letters) had to be copied by hand. (If more were needed, the document would have to go to the printers.) After the run had been copied, business partners had to read each one to ensure that they were all exactly the same, and that human error or tiredness had not introduced an error into one copy. The process was time consuming and frustrating for all. The stencil copy method meant that only one copy had to be read, as all copies were mechanically identical.

...

Wikipedia