Boundary Dam Power Station

| Boundary Dam Power Station | |

|---|---|

|

|

| Country | Canada |

| Location | Estevan No. 5, near Estevan, Saskatchewan |

| Coordinates | 49°5′47″N 103°1′49″W / 49.09639°N 103.03028°WCoordinates: 49°5′47″N 103°1′49″W / 49.09639°N 103.03028°W |

| Status | Active |

| Commission date | 1959 |

| Owner(s) | SaskPower |

| Thermal power station | |

| Primary fuel | Coal (lignite) |

| Type | Steam turbine |

| Power generation | |

| Nameplate capacity | 813 megawatts |

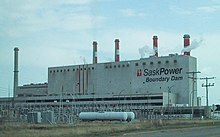

Boundary Dam Power Station is the largest coal fired station owned by SaskPower, located near Estevan, Saskatchewan, Canada.

The Boundary Dam Power Station consists of: two 62 net MW units (commissioned in 1959), two 139 net MW units (commissioned in 1970); one of which — Unit 3 — was decommissioned and replaced with a new 160 MW unit in 2013, one 139 net MW unit (commissioned in 1973) and one 273 net MW unit (commissioned in 1978).

The boilers are supplied by Babcock & Wilcox and Combustion Engineering while the turbines/generator are supplied by General Electric and Hitatchi. There is also Boundary Dam (constructed in 1957) located next to the station. It is an earth fill dam, which created the Boundary Reservoir on Long Creek a few kilometres west of the river's mouth on the Souris River. The station uses water from the reservoir for coolant, which is why Boundary Reservoir is the only body of water in Saskatchewan that doesn't freeze over during the winter months and why it's also the only body of water in Saskatchewan that supports largemouth bass. The lake's fish species include walleye, yellow perch, northern pike, burbot, largemouth bass, smallmouth bass and white sucker.

The plant has five 300 ft (91.44 m) tall smokestacks. SaskPower has advised that the project has a 30-year life.

Boundary Dam Integrated Carbon Capture and Storage Demonstration is a project to retrofit the lignite-fired Unit #3 with carbon capture and an enhanced oil recovery system. It consists of two distinct parts: Repowering of the existing Unit #3 and the installation of the Carbon Dioxide, Sulphur Dioxide and NOx capture facility. Its primary purpose is to provide a low-cost source of carbon dioxide, to the mature Weyburn Oil Field, for Enhanced Oil Recovery. It is expected to result in a 90 percent (1 million tonnes/year) reduction in CO2 emissions and will also reduce the output of Unit 3 from 139 MW to 110 MW. However, critics point out that the 90% figure refers to the percentage of total CO2 emissions captured, and that only about a half of this CO2 will be actually be permanently stored. The remainder is released into the atmosphere during capturing, and the processing in the oil field. The retrofitted unit was officially opened in October 2014, and is the world's first commercial-scale, lignite-fired power plant equipped with carbon capture and storage technology

...

Wikipedia