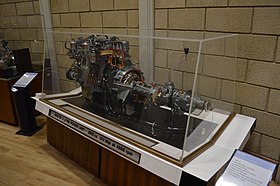

BMC C-Series engine

| BMC C-Series Engine | |

|---|---|

|

|

| Overview | |

| Manufacturer | BMC |

| Production | 1954 - 1971 |

| Combustion chamber | |

| Configuration | OHV I6 |

| Displacement | 2,639 cc (161.0 cu in) 2,912 cc (177.7 cu in) |

| Cylinder bore | 79.4 (2.6 L) 83.4 (2.9 L) |

| Piston stroke | 88.9 |

| Cylinder block alloy | Cast Iron |

| Cylinder head alloy | Cast Iron |

| Valvetrain | OHV, Duplex Chain drive |

| Combustion | |

| Fuel system | 1, 2 or 3 Carburettor(s) |

| Fuel type | Petrol |

| Cooling system | Watercooled |

| Output | |

| Power output | 63 kW (86 PS)→76 kW (103 PS) (2.6 L) 76 kW (103 PS)→112 kW (152 PS) (2.9 L) |

| Dimensions | |

| Dry weight | 1954-1967 271 kg (597 lb) 1967-1971 251 kg (553 lb) |

| Chronology | |

| Successor | BMC E-Series engine |

The BMC C-Series was a straight-6 automobile engine produced from 1954 to 1971. Unlike the Austin-designed A-Series and B-Series engines, it came from the Morris Engines drawing office in Coventry and therefore differed significantly in its layout and design from the two other designs which were closely related. Displacement was 2.6 to 2.9 L with an undersquare stroke of 88.9 mm, bored out to increase capacity.

The new engine was required to replace BMC's inherited diverse collection of 2½-litre engines made to prewar designs and Austin's wartime designed four-cylinder BS1. A long-stroke engine, though closer to square than BMC contemporaries, with a cast iron block and cylinder head using Weslake patents, its overhead valves were operated by pushrods. Previously, Rileys used high-mounted twin camshafts with short pushrods, and Wolseleys used single overhead camshafts. The twin-cam Riley and OHC Wolseley engines were expensive to make, sold in low volumes and both had had reliability problems, especially with overheating valves under sustained high loads. The brief for the C-Series was to a be a more conventional design that was easy to build and service, more refined than the existing big Austin four-cylinder power units and with an emphasis on reliability and a long service life. At the design stage high performance was not foreseen as BMC had no sporting models of a size requiring an engine like the C-Series.

The biggest design difference between the Morris-designed C-Series and the Austin-penned A- and B-Series engines was the position of the camshaft - on the right-hand side of the block (as viewed from within the car) rather than the left, although all three engines had their inlet and exhaust ports on the left. This meant that the C-Series didn't require the compound ports of the Austin engines, which were partly required to provide space in the cylinder head for the pushrods. This should, theoretically, have provided the C-Series with superior 'breathing' and efficiency than the smaller engines since it still used the same highly-effective heart-shaped Combustion chamber design by Harry Weslake. However this was undermined by the carburettor arrangements; instead of a dedicated intake manifold the C-Series was designed with an intake gallery cast into the cylinder head, with the carburettor(s) attached directly to the intake(s). This design was chosen for ease of construction and to allow different carburettor arrangements to be easily accommodated and the design also eliminated carburetor icing. Each cylinder had a generous-sized intake port from the gallery but the restrictive shape of the gallery and the carburettor port(s) severely limited the engine's maximum power output and speed, as did the four-bearing crankshaft. There appear to have been plans for a twin cam variant of the C-Series, using the same basic head and valve design as the DOHC B-Series in the MGA Twin Cam for use in Rileys and Wolseleys. This explains the relatively unadventurous design of the standard engine. However the reliability problems of the twin-cam B-Series and the mixed reception of the Riley Pathfinder discouraged BMC from pursuing this development and work stopped in 1955.

...

Wikipedia