Allyl alcohol

|

|

|

|

| Names | |

|---|---|

|

Preferred IUPAC name

Prop-2-en-1-ol

|

|

| Other names

Allyl alcohol

1-Propen-3-ol Vinyl carbinol |

|

| Identifiers | |

|

107-18-6 |

|

| 3D model (Jmol) | Interactive image |

| ChEBI |

CHEBI:16605 |

| ChEMBL |

ChEMBL234926 |

| ChemSpider |

13872989 |

| ECHA InfoCard | 100.003.156 |

| KEGG |

C02001 |

| PubChem | 7858 |

| UNII |

3W678R12M0 |

|

|

|

|

| Properties | |

| C3H6O | |

| Molar mass | 58.08 g·mol−1 |

| Appearance | colorless liquid |

| Odor | mustard-like |

| Density | 0.854 g/ml |

| Melting point | −129 °C |

| Boiling point | 97 °C (207 °F; 370 K) |

| Miscible | |

| Vapor pressure | 17 mm Hg |

| -36.70·10−6 cm3/mol | |

| Hazards | |

| Safety data sheet | External MSDS |

|

EU classification (DSD)

|

Toxic (T) Dangerous for the environment (N) |

| R-phrases |

R10, R23/24/25, R36/37/38, R50 |

| S-phrases |

(S1/2), S36/37/39, S38, S45, S61 |

| NFPA 704 | |

| Flash point | 21 °C (70 °F; 294 K) |

| 378 °C (712 °F; 651 K) | |

| Explosive limits | 2.5–18.0% |

| Lethal dose or concentration (LD, LC): | |

|

LC50 (median concentration)

|

1000 ppm (mammal, 1 hr) 76 ppm (rat, 8 hr) 207 ppm (mouse, 2 hr) 1000 ppm (rabbit, 3.5 hr) 1000 ppm (monkey, 4 hr) 1060 ppm (rat, 1 hr) 165 ppm (rat, 4 hr) 76 ppm (rat, 8 hr) |

| US health exposure limits (NIOSH): | |

|

PEL (Permissible)

|

2 ppm |

|

REL (Recommended)

|

TWA 2 ppm (5 mg/m3) ST 4 ppm (10 mg/m3) [skin] |

|

IDLH (Immediate danger)

|

20 ppm |

|

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

|

|

|

|

|

| Infobox references | |

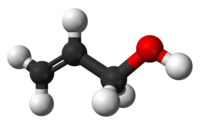

Allyl alcohol (IUPAC name: prop-2-en-1-ol) is an organic compound with the structural formula CH2=CHCH2OH. Like many alcohols, it is a water-soluble, colourless liquid, but it is more toxic than typical small alcohols. Allyl alcohol is used as a raw material for the production of glycerol, but is also used as a precursor to many specialized compounds such as flame-resistant materials, drying oils, and plasticizers. Today allyl alcohol can be obtained by many methods. Allyl alcohol is the smallest representative of the allylic alcohols.

Allyl alcohol was first prepared in 1856 by Auguste Cahours and August Hofmann by saponification of allyl iodide. Today allyl alcohol is produced commercially by the Dow and Shell corporations through the hydrolysis of allyl chloride:

Allyl alcohol can also be made by the rearrangement of propylene oxide, a reaction that is catalyzed by potassium alum at high temperature. The advantage of this method relative to the allyl chloride route is that it does not generate salt. Also avoiding chloride-containing intermediates is the "acetoxylation" of propylene to allyl acetate:

Hydrolysis of this acetate gives allyl alcohol. In alternative fashion, propylene can be oxidized to acrolein, which upon hydrogenation gives the alcohol.

...

Wikipedia