4 inch Stokes Mortar

| 3 inch Stokes mortar | |

|---|---|

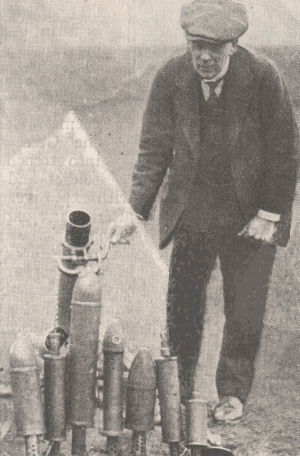

Sir Wilfred Stokes with example of his mortar and bombs. Typical 3-inch bombs used are 2nd and 6th from left

|

|

| Type | Light mortar |

| Place of origin | United Kingdom |

| Service history | |

| Used by |

|

| Wars | |

| Production history | |

| Designer | Sir Wilfred Stokes KBE |

| Designed | 1915 |

| Specifications | |

| Weight | 104 lbs (47.17 kg) total |

| Crew | 2 |

|

|

|

| Shell |

HE 10 lb 11 oz (4.84 kg) |

| Calibre | 3.2 in (81 mm) |

| Action | Trip |

| Elevation | 45°-75° |

| Rate of fire | 25 rpm (maximum) 6-8 rpm (sustained) |

| Effective firing range | 750 yards (686 m) |

| Maximum firing range | 800 yards (731 m) |

| Filling | amatol |

| Filling weight | 2lb 4 oz (1 kg) |

The Stokes mortar was a British trench mortar invented by Sir Wilfred Stokes KBE that was issued to the British, Empire and U.S. armies, as well as the Portuguese Expeditionary Corps (CEP), during the later half of the First World War. The 3-inch trench mortar is a smooth-bore, muzzle-loading weapon for high angles of fire. Although it is called a 3-inch mortar, its bore is actually 3.2 inches or 81 mm.

Frederick Wilfred Scott Stokes – who later became Sir Wilfred Stokes KBE – designed the mortar in January 1915. The British Army was at the time trying to develop a weapon that would be a match for the Imperial German Army's Minenwerfer mortar, which was in use on the Western Front.

Stokes's design was initially rejected in June 1915 because it was unable to use existing stocks of British mortar ammunition, and it took the intervention of David Lloyd George (at that time Minister of Munitions) and Lieutenant-Colonel J. C. Matheson of the Trench Warfare Supply Department (who reported to Lloyd George) to expedite manufacture of the Stokes mortar.

The Stokes mortar was a simple weapon, consisting of a smoothbore metal tube fixed to a base plate (to absorb recoil) with a lightweight bipod mount. When a mortar bomb was dropped into the tube, an impact sensitive primer in the base of the bomb would make contact with a firing pin at the base of the tube, and detonate, firing the bomb towards the target.

The barrel is a seamless drawn-steel tube necked down at the breech or base end. To the breech end is fitted a base cap, within which is secured a firing pin protruding into the barrel. The caps at each end of the bomb cylinder were 81 mm diameter. The bomb was fitted with a modified hand grenade fuze on the front, with a perforated tube containing a propellant charge and an impact-sensitive cap at the rear.

...

Wikipedia