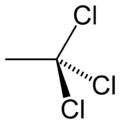

1,1,1-Trichloroethane

|

|

|||

| Names | |||

|---|---|---|---|

|

IUPAC name

1,1,1-trichloroethane

|

|||

| Other names

methyl chloroform, chlorothene, Solvent 111, Genklene, R-140a

|

|||

| Identifiers | |||

|

71-55-6 |

|||

| 3D model (Jmol) | Interactive image | ||

| ChEBI |

CHEBI:36015 |

||

| ChEMBL |

ChEMBL16080 |

||

| ChemSpider |

6042 |

||

| ECHA InfoCard | 100.000.688 | ||

| 5482 | |||

| KEGG |

C18246 |

||

| PubChem | 6278 | ||

| UNII |

113C650IR1 |

||

|

|||

|

|||

| Properties | |||

| C2H3Cl3 or CH3CCl3 | |||

| Molar mass | 133.40 g/mol | ||

| Appearance | Colorless liquid | ||

| Odor | mild, chloroform-like | ||

| Density | 1.32 g/cm3 | ||

| Melting point | −33 °C (−27 °F; 240 K) | ||

| Boiling point | 74 °C (165 °F; 347 K) | ||

| 0.4% (20°C) | |||

| Vapor pressure | 100 mmHg (20°C) | ||

| Hazards | |||

| Main hazards | Irritant to the upper respiratory tract. Causes severe irritation and swelling to eyes. | ||

| R-phrases | R19 R20 R40 R59 R66 | ||

| S-phrases | S9 S16 S24 S25 S46 S59 S61 | ||

| NFPA 704 | |||

| Explosive limits | 7.5%-12.5% | ||

| Lethal dose or concentration (LD, LC): | |||

|

LD50 (median dose)

|

9600 mg/kg (oral, rat) 6000 mg/kg (oral, mouse) 5660 mg/kg (oral, rabbit) |

||

|

LC50 (median concentration)

|

3911 ppm (mouse, 2 hr) 18000 ppm (rat, 4 hr) |

||

| US health exposure limits (NIOSH): | |||

|

PEL (Permissible)

|

TWA 350 ppm (1900 mg/m3) | ||

|

REL (Recommended)

|

C 350 ppm (1900 mg/m3) [15-minute] | ||

|

IDLH (Immediate danger)

|

700 ppm | ||

|

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

|

|||

|

|

|||

| Infobox references | |||

The organic compound 1,1,1-trichloroethane, also known as methyl chloroform, is a chloroalkane. This colourless, sweet-smelling liquid was once produced industrially in large quantities for use as a solvent. It is regulated by the as an ozone-depleting substance and its use is being rapidly phased out.

1,1,1-Trichloroethane was first reported by Henri Victor Regnault in 1840. Industrially, it is usually produced in a two-step process from vinyl chloride. In the first step, vinyl chloride reacts with hydrogen chloride at 20-50 °C to produce 1,1-dichloroethane:

This reaction is catalyzed by a variety of Lewis acids, mainly aluminium chloride, iron(III) chloride, or zinc chloride. The 1,1-dichloroethane is then converted to 1,1,1-trichloroethane by reaction with chlorine under ultraviolet irradiation:

This reaction proceeds at 80-90% yield, and the hydrogen chloride byproduct can be recycled to the first step in the process. The major side-product is the related compound 1,1,2-trichloroethane, from which the 1,1,1-trichloroethane can be separated by distillation.

A somewhat smaller amount of 1,1,1-trichloroethane is produced from the reaction of vinylidene chloride and hydrogen chloride in the presence of an iron(III) chloride catalyst:

1,1,1-Trichloroethane is marketed with stabilizers since it is unstable with respect to dehydrochlorination and attacks some metals. Stabilizers comprise up to 8% of the formulation, including acid scavengers (epoxides, amines) and complexants. The Montreal Protocol targeted 1,1,1-trichloroethane as one of those compounds responsible for ozone depletion and banned its use beginning in 1996. Since then, its manufacture and use has been phased out throughout most of the world.

...

Wikipedia