Trap (printing)

Trap on a press is the ability of a printed ink to accept the next printed ink compared to how well paper accepts that ink. Registration is when all printed images are lined up over one another. Trapping is a term originally used as a measure of how well one ink printed on top of another. With the advent of Pre-press Software the term was misused to describe the compensation for misregistration between printing units on a multicolor press that was traditionally known as "Chokes and Spreads". This misregistration causes unsightly gaps or white-space on the final printed work. Trapping involves creating overlaps (spreads) or underlaps (chokes) of objects during the print production process to eliminate misregistration on the press.

Misregistration in the graphical workflow may be caused by a number of reasons: inaccuracies in the image setter, instability of the image carrier (e.g., stretch in film or plate), inaccuracy in the film-to-plate or film-to-film copying steps, instability of the press, instability of the final media, and human error.

These inaccuracies are inherent to the graphical production process and although they can be minimized, they will never completely disappear - any mechanical process will always show some margin of error. The small gaps showing up as a result can, however, be hidden by creating overlaps between two adjacent colors.

One approach to trapping is to change the submitted artwork. In general, all digital files produced using any current professional software have some level of trapping provided already, via application default values. Additional trapping may also be necessary, but all traps should be as unobtrusive as possible.

Traps can be applied at several stages in the digital workflow, using one of two trapping technologies: vector-based and raster-based. The right choice will depend on the type of products (packaging applications including flexo-printing have other requirements than commercial printing on offset systems) and the degree of interactivity or automation that is wanted.

In-RIP trapping moves the trapping to the RIP so that it is done at the last moment. The process is automatic, although it is possible to set up zones to allow different automatic rules for different areas, or to disable trapping for areas previously manually trapped.

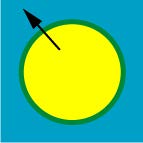

It is important to know that the darker color always keeps its shape. The neutral density of a color is used to determine its darkness.

The lighter color can trap the darker color in the following directions:

...

Wikipedia