Terephthalic acid

|

|

|

|

| Names | |

|---|---|

|

Preferred IUPAC name

Benzene-1,4-dicarboxylic acid

|

|

| Other names

Terephthalic acid

para-Phthalic acid TPA PTA BDC |

|

| Identifiers | |

|

100-21-0 |

|

| 3D model (Jmol) | Interactive image |

| ChEBI |

CHEBI:15702 |

| ChemSpider |

7208 |

| ECHA InfoCard | 100.002.573 |

| RTECS number | WZ0875000 |

| UNII |

6S7NKZ40BQ |

|

|

|

|

| Properties | |

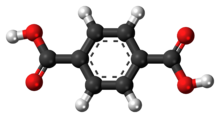

| C8H6O4 | |

| Molar mass | 166.13 g/mol |

| Appearance | white crystals or powder |

| Density | 1.522 g/cm³ |

| Melting point | 300 °C (572 °F; 573 K) in a sealed tube; sublimes at 402 °C (756 °F; 675 K) |

| Boiling point | Decompose |

| 0.0015 g/100 mL at 20°C | |

| Solubility | polar organic solvents aqueous base |

| Acidity (pKa) | 3.51, 4.82 |

| -83.51·10−6 cm3/mol | |

| Structure | |

| zero | |

| Hazards | |

| Safety data sheet |

See: data page MSDS sheet |

|

EU classification (DSD)

|

not listed |

| Related compounds | |

|

Related carboxylic acids

|

Phthalic acid Isophthalic acid Benzoic acid p-Toluic acid |

|

Related compounds

|

p-Xylene Polyethylene terephthalate Dimethyl terephthalate |

| Supplementary data page | |

|

Refractive index (n), Dielectric constant (εr), etc. |

|

|

Thermodynamic

data |

Phase behaviour solid–liquid–gas |

| UV, IR, NMR, MS | |

|

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

|

|

|

|

|

| Infobox references | |

Terephthalic acid (a portmanteau of the turpentine-producing tree terebinthus, and phthalic acid) is the organic compound with formula C6H4(CO2H)2. This white solid is a commodity chemical, used principally as a precursor to the polyester PET, used to make clothing and plastic bottles. Several million tonnes are produced annually.

Terephthalic acid was first isolated (from turpentine) by the French chemist Amédée Cailliot (1805-1884) in 1846. The importance of the terephthalic acid was realized after World War II. The first companies to commercialize the use of the fibers made from polyethylene terephthalate were Imperial Chemical Industries in the UK in 1949 and DuPont in the US in 1953. The fibers were made from dimethyl terephthalate by transesterification with ethylene glycol. Terephthalic acid was produced by oxidation of p-xylene with dilute nitric acid. This type of oxidation involved the use of air in the initial oxidation step to minimize the consumption of nitric acid and difficulty in purification. Growth in the textile industry led to increase in demand of TPA. In the 1960s, all the terephthalic acid produced was converted to its dimethyl ester, since TPA was infusible and difficult to purify. Presently TPA is manufactured by oxidation of p-xylene.

Terephthalic acid is poorly soluble in water and alcohols; consequently, until about 1970 terephthalic acid was purified as its dimethyl ester. It sublimes when heated.

In the Amoco process, terephthalic acid is produced by oxidation of p-xylene by oxygen in air:

...

Wikipedia