International Scout

| International Scout | |

|---|---|

|

|

| Overview | |

| Manufacturer | International Harvester |

| Production | 1961–1980 |

| Assembly | Fort Wayne, Indiana |

| Body and chassis | |

| Class | Full-size SUV |

| Body style | 2-door SUV 2-door Pickup Truck |

| Layout | Front engine, rear-wheel drive / four-wheel drive |

| International Scout 800 | |

|---|---|

|

|

| Overview | |

| Manufacturer | International Harvester |

| Production | 1965–1968 |

| Powertrain | |

| Engine | 152 cu in (2.5 L) Comanche I4 196 cu in (3.2 L) I4 232 cu in (3.8 L) I6 266 cu in (4.4 L) V8 |

| Chronology | |

| Predecessor | International Scout 80 |

| Successor | International Scout 800A |

| International Scout 800A | |

|---|---|

| Overview | |

| Manufacturer | International Harvester |

| Production | November 1968 – 1970 |

| Body and chassis | |

| Related | 1000 D-Series pickup |

| Powertrain | |

| Engine | 152 cu in (2.5 L) Comanche I4 196 cu in (3.2 L) I4 232 cu in (3.8 L) I6 266 cu in (4.4 L) V8 304 cu in (5.0 L) V8 |

| Chronology | |

| Predecessor | International Scout 800 |

| Successor | International Scout 800B |

| International Scout 800B | |

|---|---|

| Overview | |

| Manufacturer | International Harvester |

| Production | August 1970 - March 1971 |

| Chronology | |

| Predecessor | International Scout 800A |

| Successor | International Scout II |

| International Scout II | |

|---|---|

|

|

| Overview | |

| Manufacturer | International Harvester |

| Production | April 1971 – 1980 |

| Chronology | |

| Predecessor | International Scout 800B |

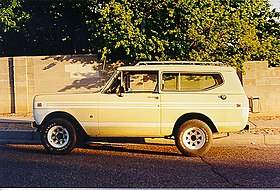

The International Harvester Scout is an off-road vehicle which was produced by International Harvester from 1961 to 1980. A precursor of more sophisticated SUVs to come, it was created as a competitor to the Jeep, and it initially featured a fold-down windshield. The Scout and second generation Scout II were produced in Fort Wayne, Indiana as two-door trucks with a removable hard top with options of a full length roof, half cab pickup and/or soft top.

International Harvester began building trucks and pickups in 1907. In 1953 it added a truck-based people carrier, the Travelall. In the late 1950s it began to design a competitor for the two-door Jeep CJ 4x4. The 1961 model year Scout 80 made its debut in late 1960.

Its chief designer Ted Ornas later reflected:

...the market potential for a 4 wheel drive recreational vehicle was an unknown quantity in the early 1950s. The only such vehicle offered in the post-war period was the Willys Jeep, a version of the military jeep produced for World War II. It was a flat-sided bare-bones product, and American military personnel learned to appreciate its ability to maneuver over rough terrain. Sales volume was very low. In early 1958 we were directed to develop a concept proposal to enter this small market of that time. So help me, Mr. Reese, manager of engineering, said 'design something to replace the horse.' There was no product definition to use as a guide. It was even proposed to use the defunct Henry J body tooling. Compound body surfaces were considered too far out for this type of vehicle. The military jeep was thought to have the correct appearance. Our design sketches with the flat-side, no contour look never excited the executive committee. The program began to die. One night while sitting at our kitchen table (full of frustration and desperation), I dashed off this rough sketch on a piece of scrap mat board. It had contoured sides and was designed for plastic tooling. The next morning it was shown to a committee member. He reviewed it with controlled enthusiasm, but revived interest in the program. We were off and running. Goodyear produced many plastic parts for WWII and had formed a large plastic engineering group. We entered a program with them, a scale model was vacuum formed to simulate body assembly. This model received executive approval for appearance. By July 1959, Goodyear completed their costing and, because of the high costs, the plastic program was cancelled. By this time the contoured design met with executive approval and a decision was made to convert the body design to steel. Starting in late July 1959 a full size clay model was completed, and in November 1959, it was approved. Looking back, it was a remarkable program with fast paced engineering and manufacturing developments. The total development time of 24 months was an heroic achievement considering the concept was unique and no in-house engine or manufacturing was available or even considered when the program started.

...

Wikipedia