Hydrofracking

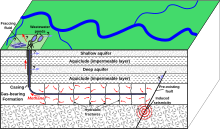

Schematic depiction of hydraulic fracturing for shale gas

|

|

| Process type | Mechanical |

|---|---|

| Industrial sector(s) | Mining |

| Main technologies or sub-processes | Fluid pressure |

| Product(s) | Natural gas, petroleum |

| Inventor | Floyd Farris, Joseph B. Clark (Stanolind Oil and Gas Corporation) |

| Year of invention | 1947 |

Hydraulic fracturing (also fracking, fraccing, hydrofracturing or hydrofracking) is a well stimulation technique in which rock is fractured by a pressurized liquid. The process involves the high-pressure injection of 'fracking fluid' (primarily water, containing sand or other proppants suspended with the aid of thickening agents) into a wellbore to create cracks in the deep-rock formations through which natural gas, petroleum, and brine will flow more freely. When the hydraulic pressure is removed from the well, small grains of hydraulic fracturing proppants (either sand or aluminium oxide) hold the fractures open.

Hydraulic fracturing began as an experiment in 1947, and the first commercially successful application followed in 1950. As of 2012, 2.5 million "frac jobs" had been performed worldwide on oil and gas wells; over one million of those within the U.S. Such treatment is generally necessary to achieve adequate flow rates in shale gas, tight gas, tight oil, and coal seam gas wells. Some hydraulic fractures can form naturally in certain veins or dikes.

Hydraulic fracturing is highly controversial in many countries. Its proponents advocate the economic benefits of more extensively accessible hydrocarbons.Opponents argue that these are outweighed by the potential environmental impacts, which include risks of ground and surface water contamination, air and noise pollution, and the triggering of earthquakes, along with the consequential hazards to public health and the environment.

...

Wikipedia